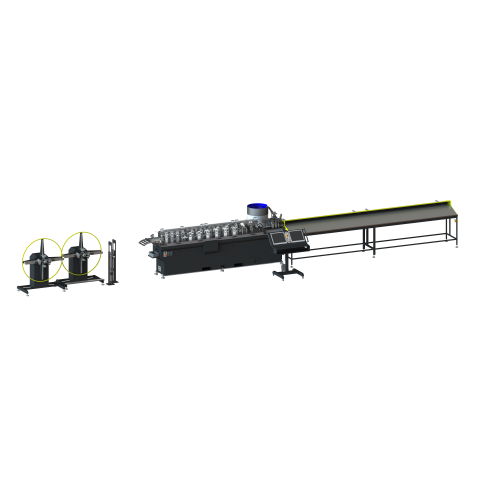

This is the universal rolling line for upper and lower profiles, including punching and dividing with the possibility of automatically inserting plastic parts into the upper profile directly in the machine. This machine is particularly suitable for large companies.

There are two lines for rolling in this rolling line and each is driven by a separate servomotor, thereby ensuring independent processing of individual profiles.

The rolling line can process profiles in two ways: direct entry of dimensions into the machine according to a job order or only the production of profiles in lengths specified for further processing in the subsequent machine.

The machine is operated by using a touch display panel. The rolling line can be connected to the local network, making it possible to enter dimensions of job orders from the customer's information system. Possible software failures can be remotely diagnosed and corrected through a built-in modem.

An advantage of this rolling line is the fact that almost all operations are performed directly in it and there is no need for a rolled profile to be put into other tools. Further advantages are: savings of materials, areas for storage of profiles and production time.

- line for the rolling of upper and lower profiles for horizontal interior blinds

- two active unrolling devices with ultrasonic sensor

- punching of all necessary holes in profiles

- dividing of profiles to the required size

- inserting of the plastic bearing into the upper profile

- marking of the upper profile using Laser-JET or INK-JET technology with the possibility of barcode printing

- stacking table

- possible custom or length production

- machine productivity:1 m long profiles with three holes with grooved plastic bearings up to 10 seconds