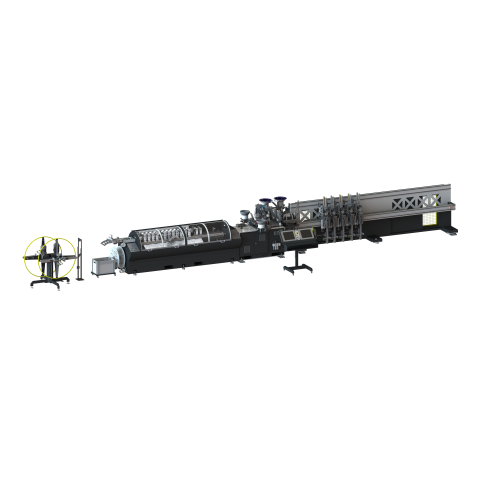

A single-purpose rolling line for production of up to 3 slat types of horizontal exterior blinds C, S, Z or Flach (according to the customer´s requirements).

The transformation of rolling wheels is performed by turning the whole worktable with , including the reconstruction of all working parts.

Characteristics:

- unrolling device

- 3 sets of rolling wheels

- tool for punching holes for TEXBAND

- tool for punching of various holes for guiding pins or side guiding

- pneumatic dividing tool

- cutting-out of fixing hooks for ladder cord fixing with slats of type C and FLACH

- shot fired fixing of flat or HAGOFIX hooks with slats type Z or S

- rolling-in of the sealing rubber with slats type Z or S (including the possibility of fixation)

- stacking table with manually or automatically adjustable stacking stands

- central tool lubrication system

- control system with touch panel

- simple entering of dimensions for manufactured slats

- two production modes: STANDARD and ATYP

A-TYPE - Optional seetting of punching holes position on the slat. Positions can be defined by entering the exact value.

STANDARD - Automatic setting of punching holes position ont the slats depending on the size of the slat

Benefits:

- increase of product quality

- noticeable savings in production costs trough automation and high productivity

- reducing the amount of the waste and defective products

- fast transition from one profile to another

- saving time and material ( due to the absence of the need to change the rolling wheels )

- turntable for three different profiles

- production of complete packets in one machine

- modem for remote diagnostics of machines

- connection of the machine to the company´s intranet

- connecting to the ETHERNET network

- RDS-mode - alows for the increase of productivity and efficiency of the production by 100% in comparison with the machines with standard configuration