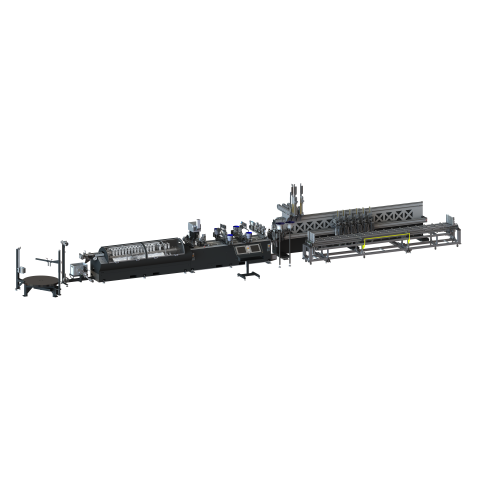

A single-purpose rolling line for production of up to 3 slat types of horizontal exterior blinds C, S, Z or Flach (according to the customer´s requirements). RDS allows the increase of daily production depending on the number of optimized tools and their distribution by 60-80% compared to conventional machine TRIANGL 14 NC.

There is no need to change rolling wheels like in case of other machines; the transformation is performed by turning the whole worktable with cylindrical wheels, including the reconstruction of all working parts.

Characteristics:

- Integrated device for unwinding 2 rolls of aluminium sheet

- 3 sets of rolling wheels including thermal treatment (hardening)

- Pneumatic tool for punching holes with edging for TEXBAND

- Tool for punching of various holes for guiding pins or side guiding

- Pneumatic dividing tool

- Cutting-out of fixing hooks for ladder cord fixing

- Shot fired fixing of flat or HAGOFIX hooks with slats type Z or S

- Rolling-in of the sealing rubber with slats type Z or S (including the possibility of fixation)

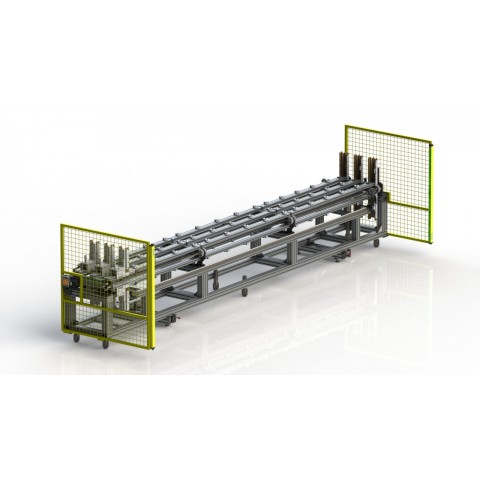

- Stacking table with manually or automatically adjustable stacking stands

- Central tool lubrication system

- Control system with touch panel

- Simple entering of dimensions for manufactured slats

- Easy adjustment of rolling speed

- Two production modes: STANDARD and ATYP

Benefits:

- High productivity

- Increase of product quality

- Noticeable savings in production costs and materials through automation and high productivity

- Revolving turntable for three different profiles

- Reducing amount of the waste and defective products

- Production of complete packet at one machine

- Possibility of automatic unwinding device for an aluminium sheet with a laser scanner

- Possibility of automatic ultrasonic welding of plastic guiding pins

- Possibility of implementing the automatic riveting device for metal guiding pins

- Possibility of automatic knotting of slats type C or FLACH to the ladder

Or

- Possibility of automatic knotting of the ladder to flat or HAGOFIX hooks for Z or S type slats

- Possibility of automatic taking-off of finished packets from the machine to a belt or compartment tray

- Possibility of automatic pressing of hooks for ladder cord fixing

- Possibility of connecting to ETHERNET

- Possibility of marking the slats with the label with barcode

- The possibility of excavation of the company logo directly into the slats

- Possibility of the connection of the machine to the company's intranet

- Modem for remote diagnostics of machine